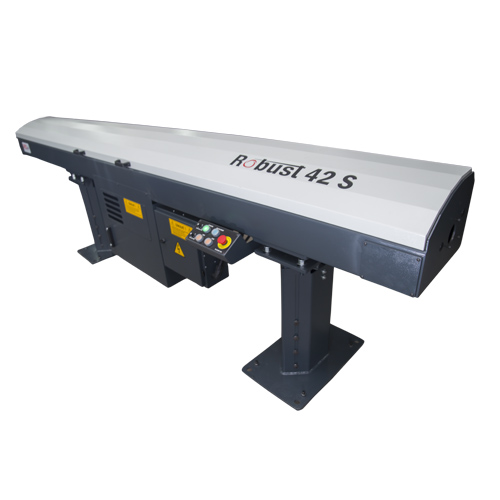

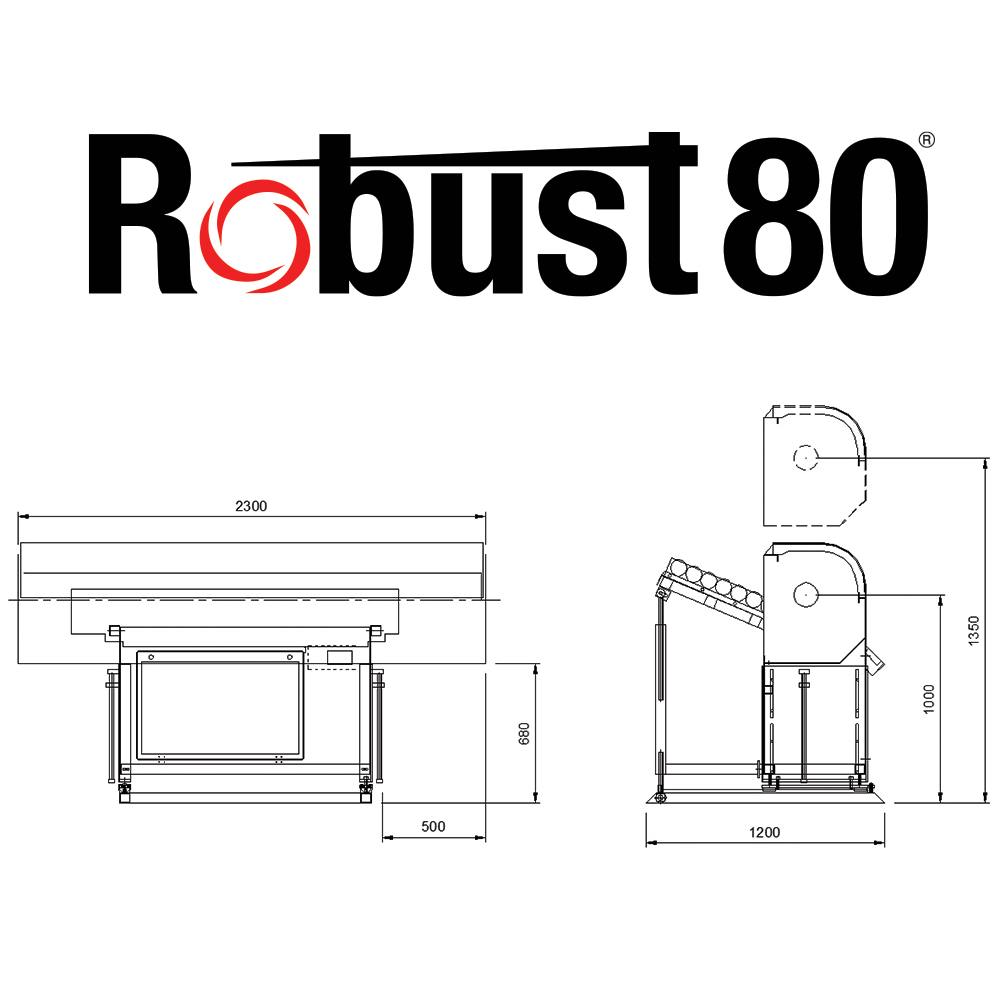

AUTOMATIC SHORT BARFEEDER

. LESS WORKING SPACE . BIG DIAMETER . HIGH RPM

Because of whole barstock is returned in spindle, there is no vibration risk. Thus, the machining can be done in required rpm.

Thanks to the servo motor, material positioning is accurate. It does not hit turret and stopper.

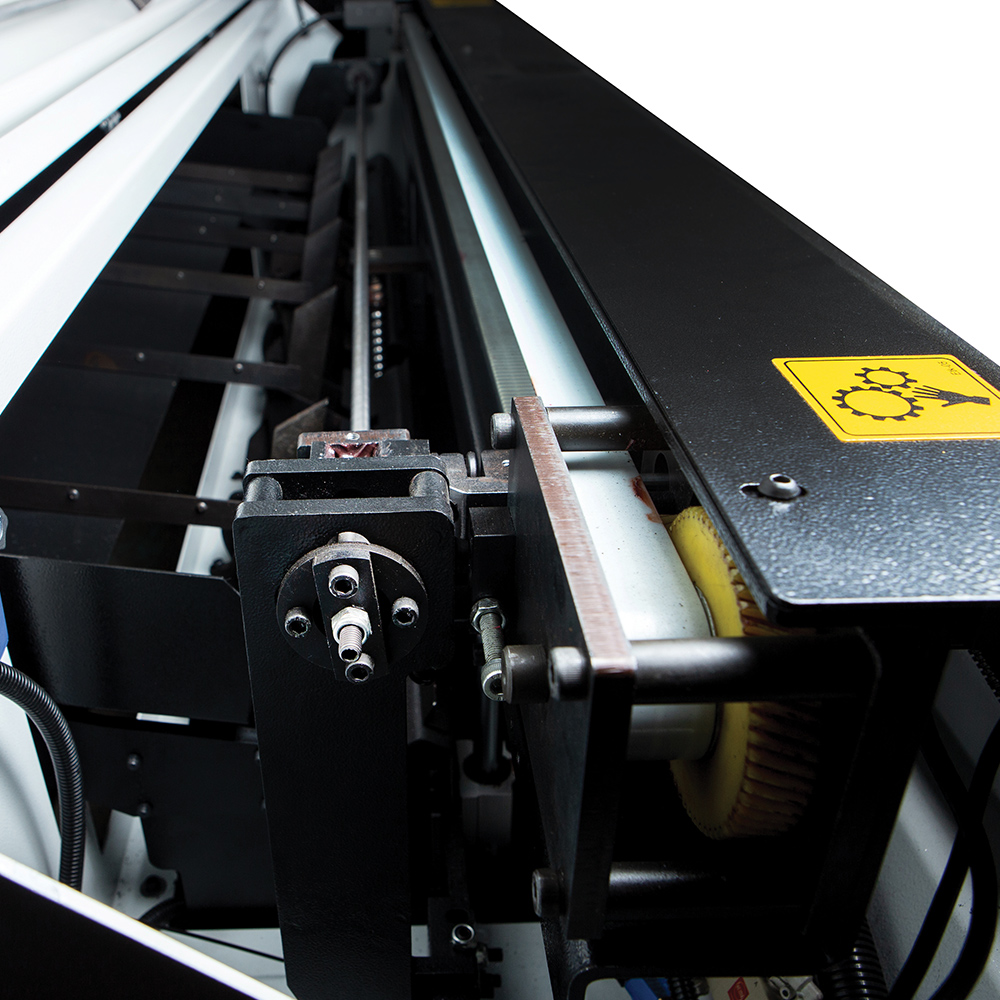

With the V type channel system suitable for every diameter, the bars move smoothly without being damaged. The short remrants can be loaded.

The beacon lamp is used to remotely observe the operating, it has user friendly touch screen.

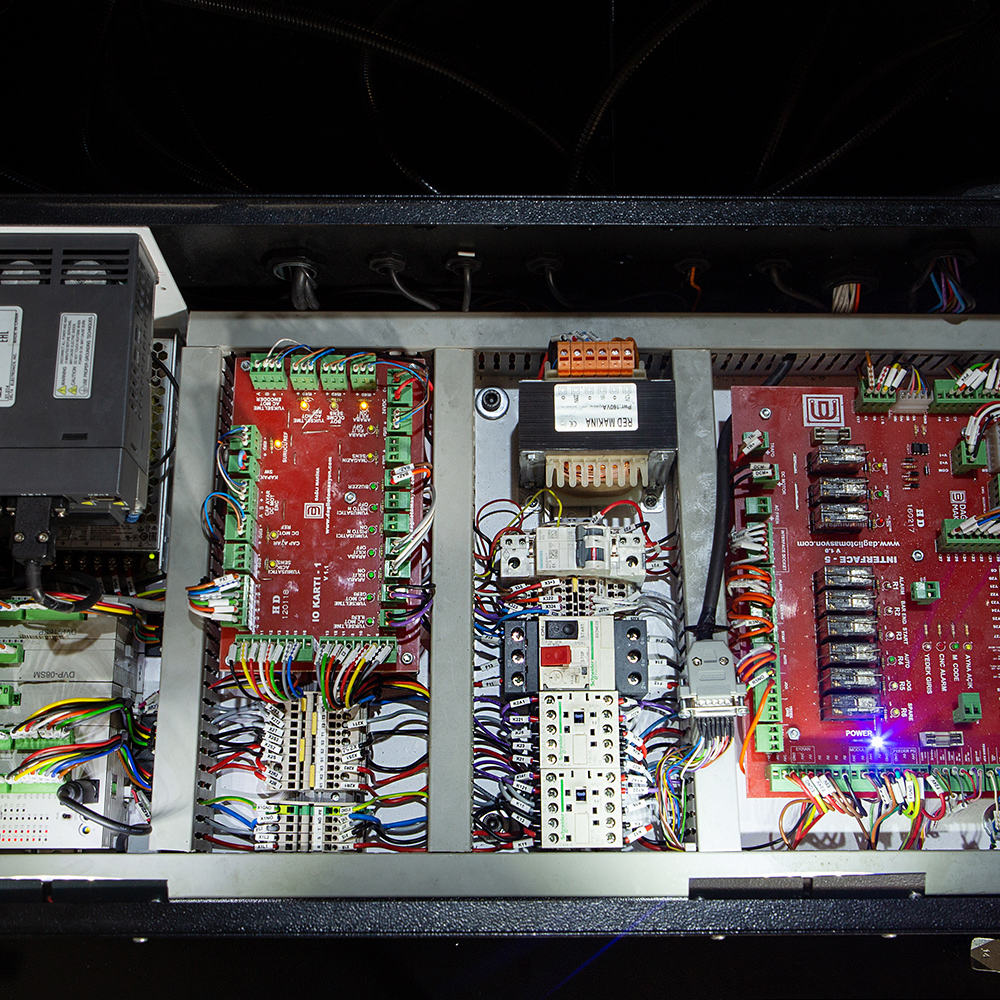

The interventions can be easily done with LED light inside the barfeeder and electric panel.

The barfeeder can be moved on X-axis rail. Thus, interventions can be easily done on lathe and headstock.

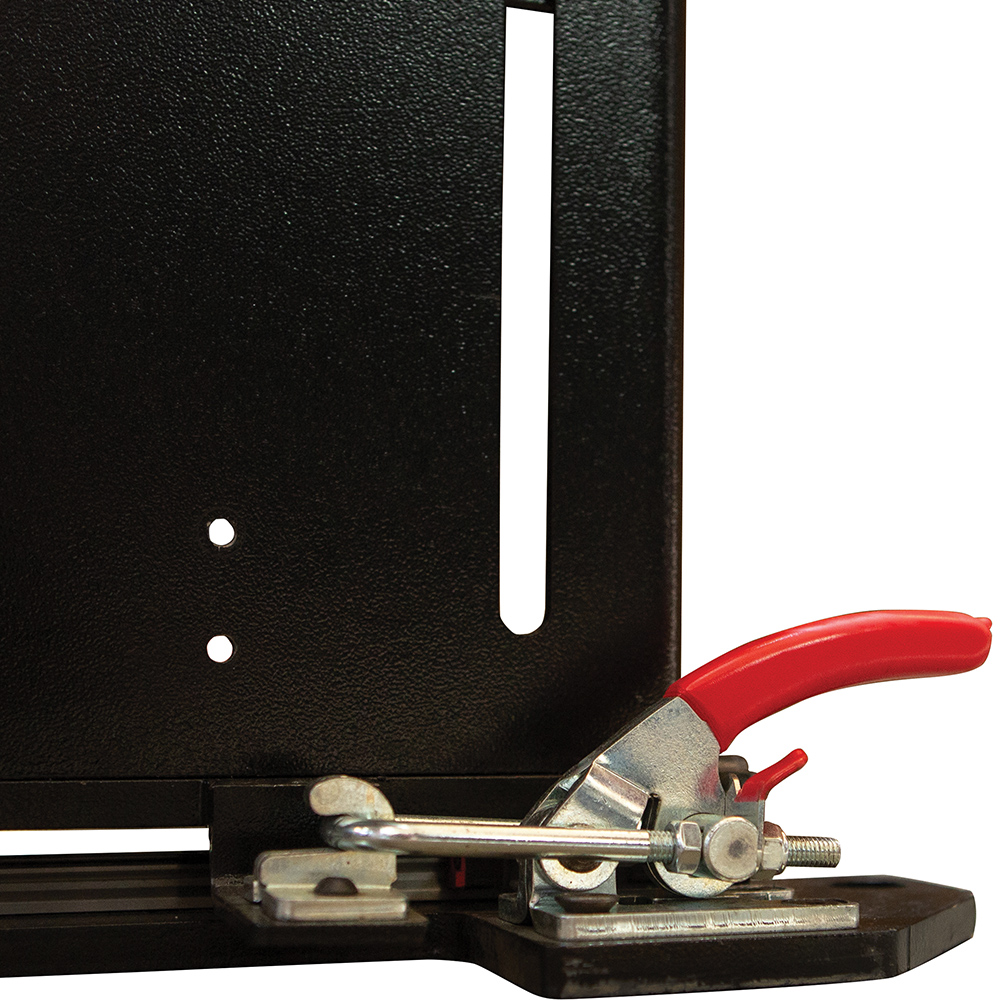

With automatic loading system and diameter setting, the diameter

changeover can be done in a short time.

| Diameter | Ø 6-80 mm |

| Diameter Setting | Automatic |

| Bar Length | 150 – 1500 mm(max.spindle length)150 – 1200 mm (max.spindle length) |

| Loading | Rear loading rack |

| Loading Capacity | 650 mm (65pcs / 10 mm) |

| Headstock Type | Fixed |

| X Axis Retraction | 500 mm |

| Motor | Servo |

| Bar Loading System | Automatic |

We produce

Other Models

There is no risk of vibration as the entire material rotates in its spindle. Especially in hexagonal, profile and large diameter materials, high speeds can be reached.

With the polyurethane casting bed and the antivibration system with easy diameter adjustment, vibration-free rotation of the material at high speeds is ensured.

With the polyurethane cast bed and V type antivibration system, vibration-free rotation of the material at high speeds is ensured.

Material positioning is sensitive. It does not hit the turret and the stop.

Thanks to the ergonomic hand control and long cable, the command buttons are used comfortably.

For Your Collaboration Requests

Schedule an online meeting with our expert team.