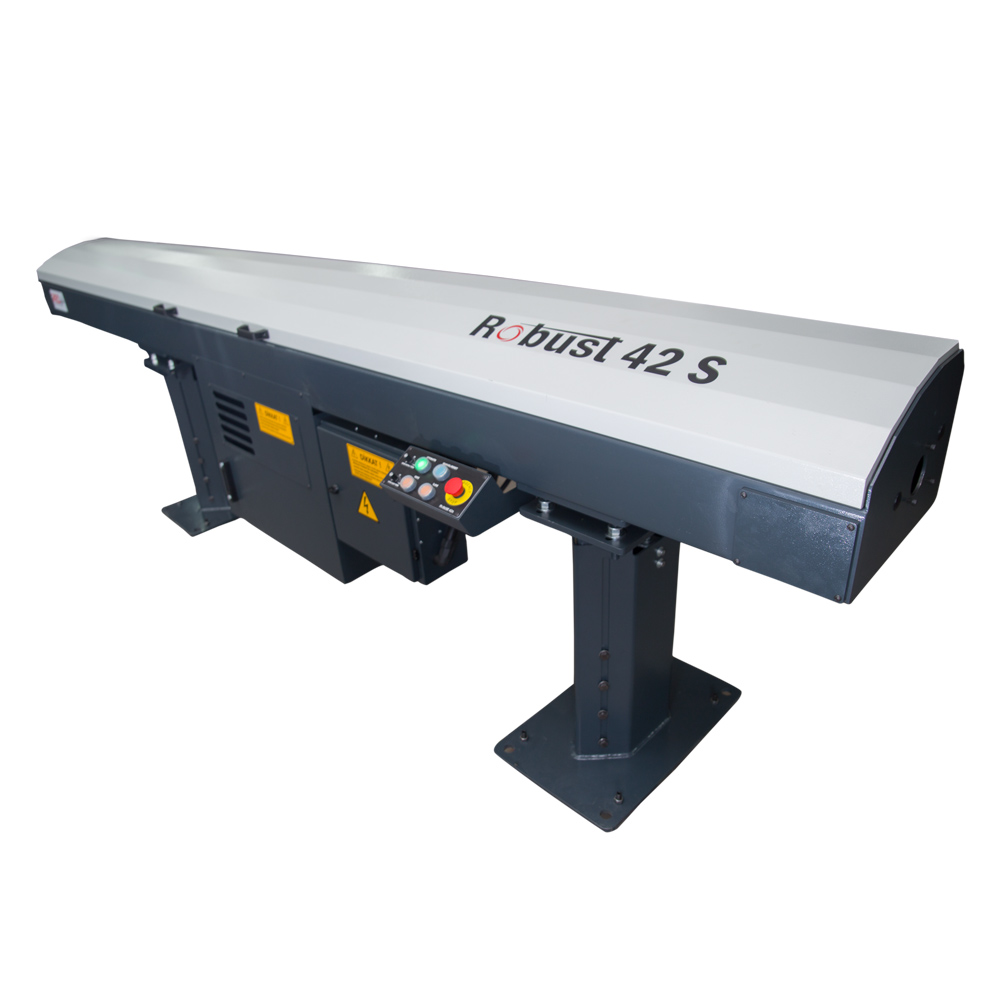

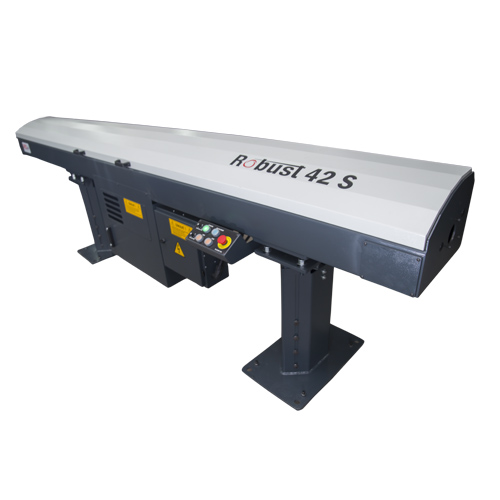

MANUAL BARFEEDER

. COMPETITIVE PRICE . LONG BAR . HIGH RPM

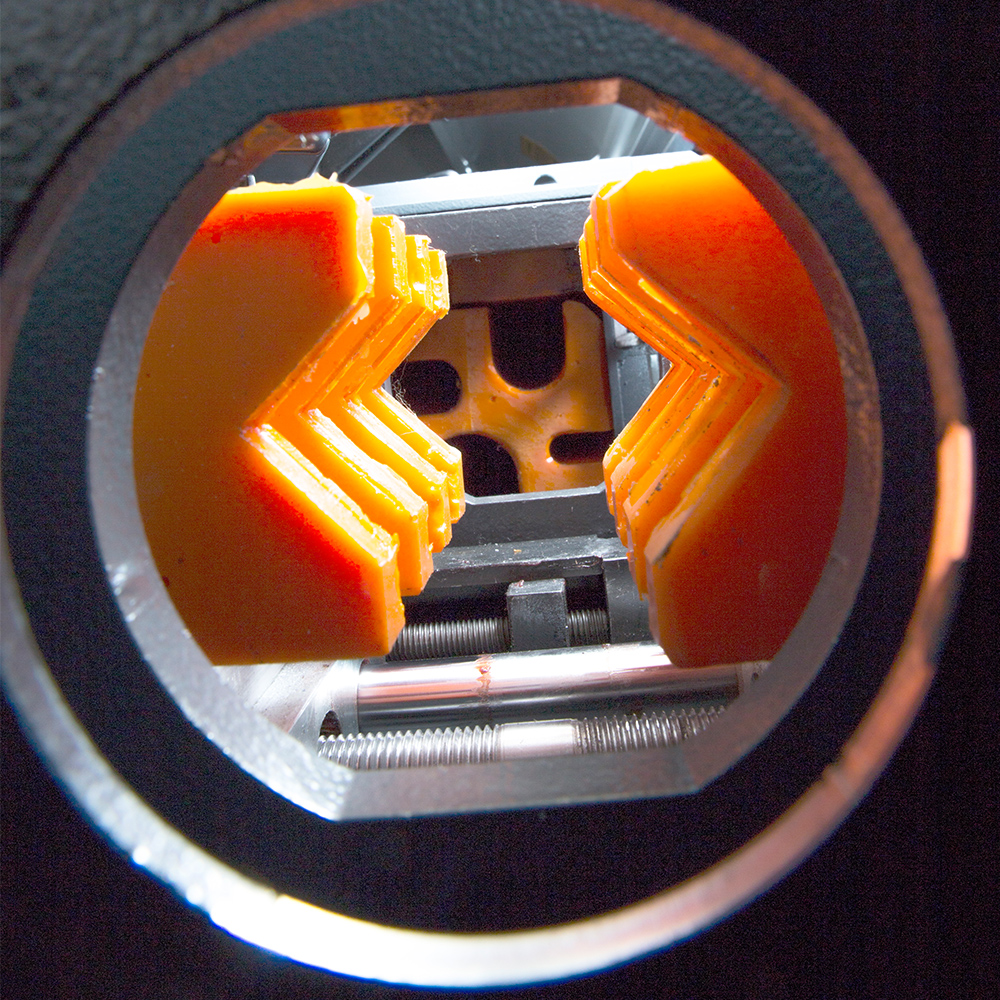

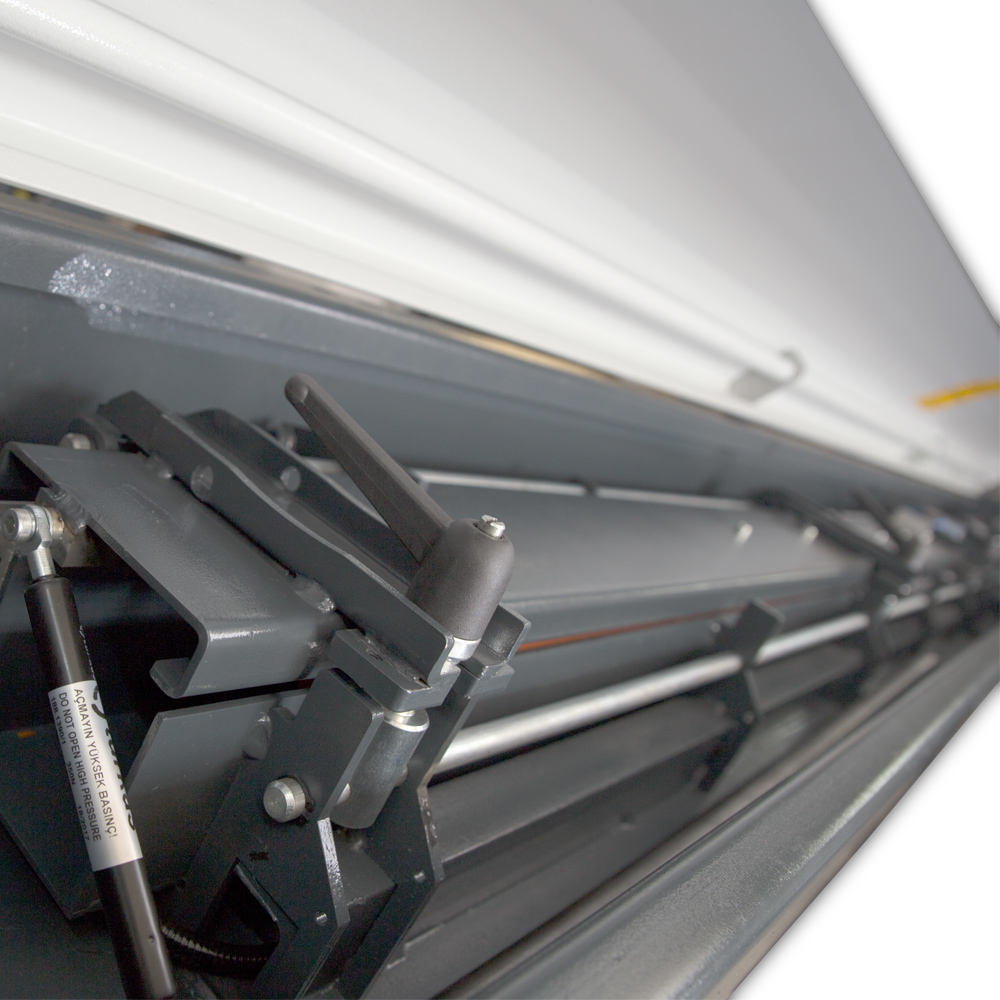

With Polyurethane molded channel and V type antivibration front rest system, the material is allowed to turn without vibration at high RPM

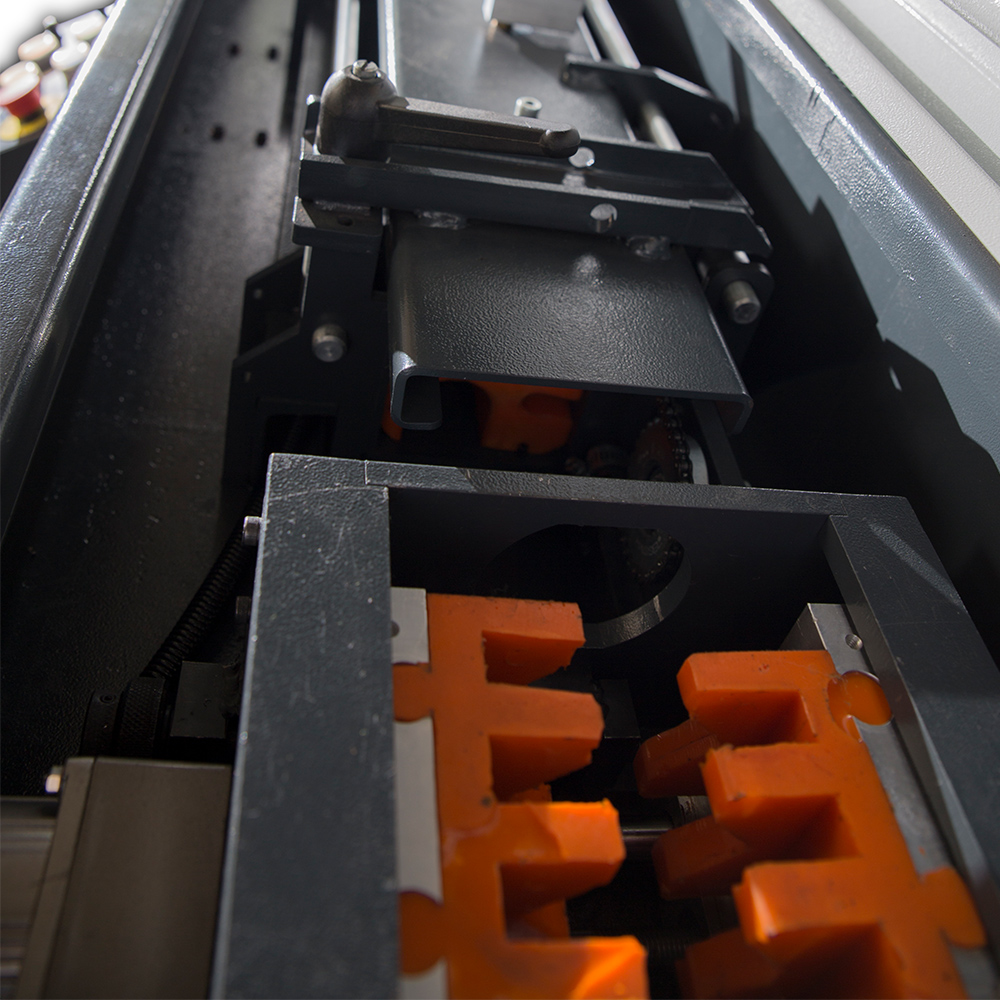

Channels with four different diameters are combined on a single monoblock channel system. Thus, diameter changeover can be done easily in a short time.

Thanks to servo motor, precise torque and speed settings suitable for bar diameters are made. In addition, chuck open/close torques can be adjusted. When the chuck is closed, no excessive torque is applied on bars. Thus, the bars turn without bending in the channel.

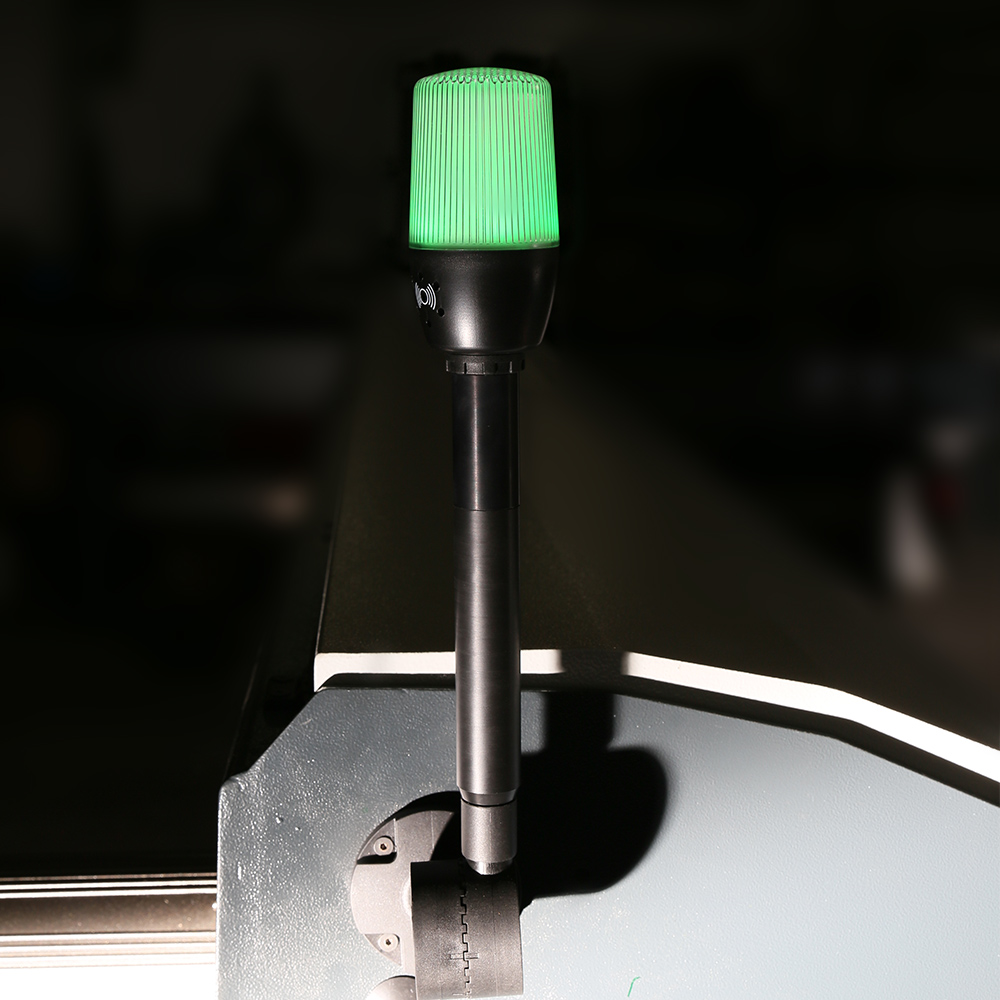

The beacon lamp is used to remotely observe the operating status of barfeeder. The interventions can be easily done with LED light inside the barfeeder and electric panel.

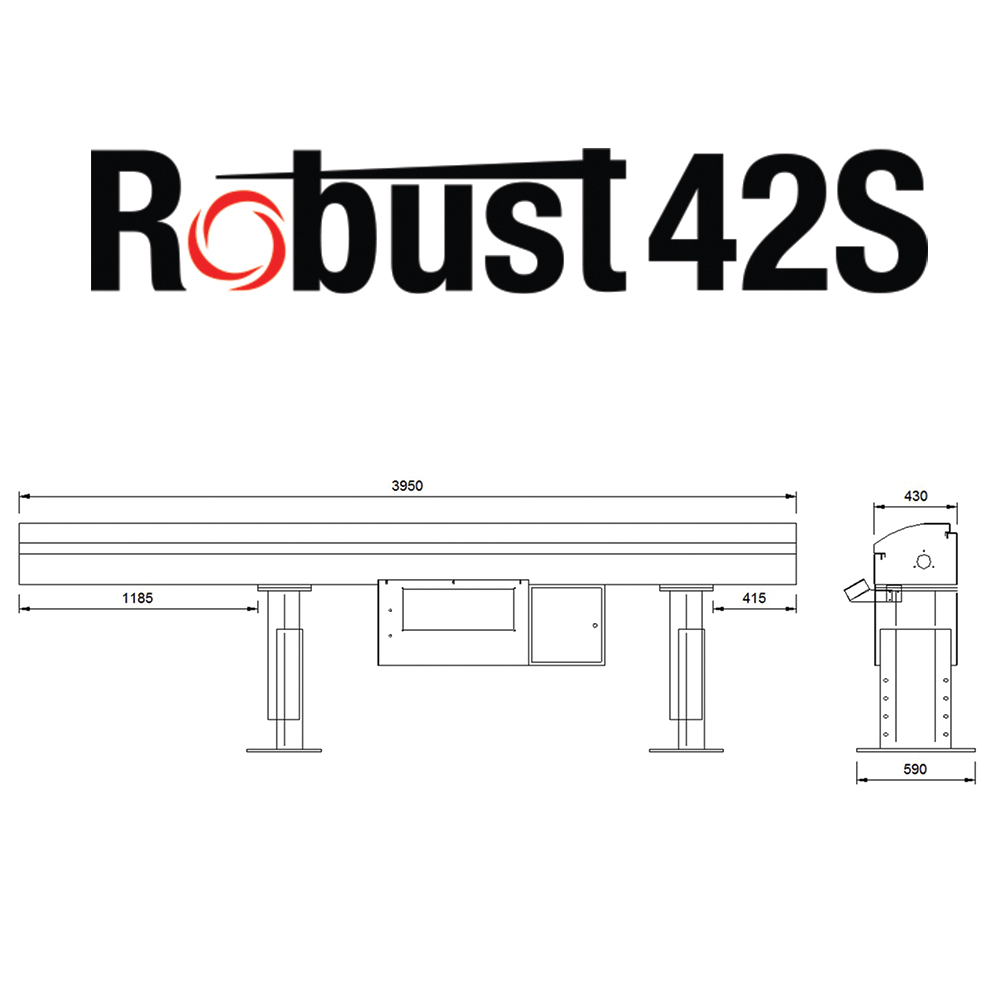

| Diameter | Ø 6-42 mm |

| Bar Length | 500 – 3000 mm |

| Bar Loading System | Manuel |

| Guiding System | 12 mm, 22mm, 32mm, 42mm in one PU block channel |

| Headstock Type | Fixed |

| Antivibration Front Rest | V type polyurethane-PU |

| Motor | Delta Servo |

We produce

Other Models

There is no risk of vibration as the entire material rotates in its spindle. Especially in hexagonal, profile and large diameter materials, high speeds can be reached.

Thanks to the servo motor, the material positioning is precise. It does not hit the turret and the brace.

With the polyurethane casting bed and the antivibration system with easy diameter adjustment, vibration-free rotation of the material at high speeds is ensured.

Thanks to the servo motor driving system, PLC and special software, precise lengthening is carried out, material backflow and measurement errors are prevented.

With the polyurethane cast bed and V type antivibration system, vibration-free rotation of the material at high speeds is ensured.

Channels of four different diameters are combined with a single monoblock bearing system. In this way, diameter changes can be made in a short time.

For Your Collaboration Requests

Schedule an online meeting with our expert team.